Dispersants reduce environmental damage from spills

Are dispersants safe to use on oil spills?

Yes. Today, dispersants are one of the fastest-acting and most efficient ways of breaking down slicks. They are regularly used as a first response to spills, as they can be applied quickly and with a minimum of equipment required.

SpillPro dispersants comply with major international regulations from:

- Environmental Protection Agency (USA)

- Marine Management Organisation (UK)

- Centre of Documentation, Research and Experimentation (France)

They are also approved for use in countries worldwide, including in Australia and New Zealand.

Using diluted and undiluted dispersants on oil spills

Our dispersants can be used diluted or 'neat' aka undiluted. How you will use it will depend on the type and scale of the oil spill you are facing, as well as the sprayer you have and your preference.

When to use diluted

If the oil spill is a thin layer and it is spread over a large area of the water's surface, then spraying it with a dilution may provide more efficient area coverage.

When to use neat

If the oil spill is thick and does not cover a very large area, spraying neat may be a better option.

When to use either

For routine treatment of small oil spills due to ships refuelling at a jetty or port, it depends on the preference of the operator. Both diluted and neat dispersants can be used.

Note: If a manual sprayer is used, dilution can lower the viscosity and make it easier to spray. Typically, the maximum sea water dilution ratio is up to 9 parts. That means 1 part OSR 52 with 9 part seawater max.

Treat rate (dosage) guidelines

Whether spraying neat or diluted, it is important to follow the treat rate (dosage) guidelines below.

| Spilled oil viscosity | Dispersant volume |

|---|---|

|

500cSt and below (at sea temperature) |

1 part dispersant can treat up to 20 part pollutant |

|

500 – 5000cSt |

1 part dispersant can treat 20 to 10 part pollutant |

|

5000 to 10,000 cSt |

1 part dispersant can treat 10 to 7 part pollutant |

Note: Normally as viscosity of the pollutant oil increases, it is recommended to spray neat instead of diluted to obtain the maximum dispersion efficiency.

Dispersant application equipment

Dispersants are applied to oil spills using spraying systems. At SpillPro, we provide 3 such systems; the Elaspray, Boomvane, and Neatsweep systems.

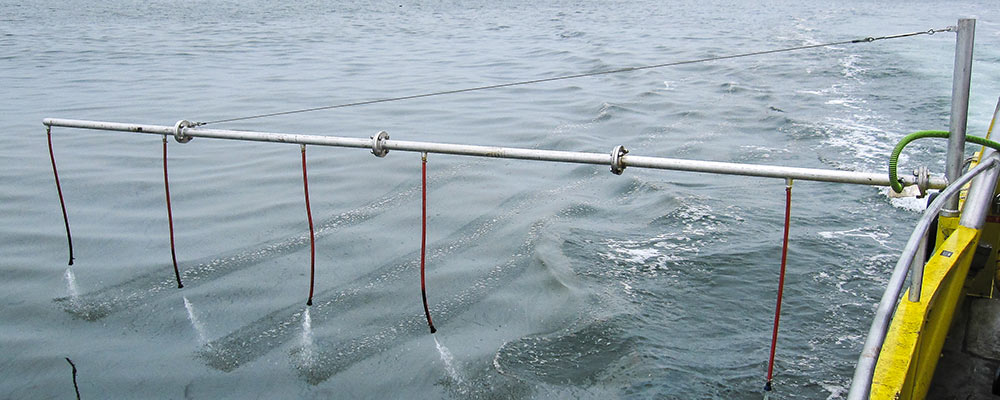

1. Elaspray System

The Elaspray system uses arms and a series of nozzles attached to a boat to spray directly onto spilt oil.

2. Boomvane Dispersant System

This system uses a boomvane which holds the spray system in position with the currents and movements of the vessel.

The spray system with nozzles are attached to a rope approximately 1 metre from the oil spill and sprayed onto the spilt oil.

These systems can be used at starboard or port. And this gives you a 40 metre swarth using a 1 metre boomvane.

3. The Neatsweep system

3. The Neatsweep system

This system works by collecting the oil in booms and then corralling it into a spray system which sprays the oil as it passes through the end of the boom system.

Thinking spills? Think SpillPro.

At SpillPro, we have been supplying local and international organisations with spill prevention and management equipment for more than 40 years.

Whatever your industry and business, we can provide you with a complete solution for spills, hydrocarbon management and workplace safety and hygiene.

To find out more about dispersants visit our dispersants page or call 1800 368 450

Must Read

SpillPro on 24 February 2025

Why Spill Readiness Matters

A spill isn't just an inconvenience. If not handled properly, it can lead to safety hazards, environmental damage, and compliance issues. By equipping your site with the right spill response solutions ...

Read moreSpillPro on 30 October 2024

Choosing the Right Containment Boom

Containment booms are the first line of defence in any spill response plan. When a spill occurs, swift and effective containment is crucial to minimise environmental impact and financial loss. Selecti ...

Read more